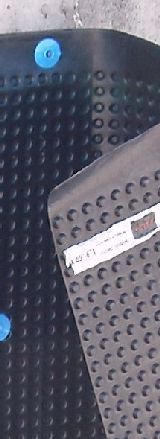

Detail of dimple design with

dimples facing the wall

|

|

Foundation wrap.

Water proofing Contractors

|

| Foundation Wrap |

|

| ...... |

Need more information? Use our search box

Foundation wrap. Water proofing foundation walls. Waterproofing contractors

The dimple designed/air gap product was first developed in Europe and has been used in Canada and the USA since the 1980s. Today it is the most common type of material used for waterproofing foundation walls.

Foundation wrap is a plastic membrane that, as the name already implies is wrapped around the foundation walls. It is an excellent waterproof barrier. This polyethylene membrane is installed from the weeping or drain pipes up to the expected finish grade. The dimple design of the wrap creates an air gap between the membrane and foundation wall so exterior drainage water or damp/wet earth is never in contact with the poured concrete or cement block foundation wall. Instead water will be drained to the weeping or drain tiles, leaving the foundation walls dry.

The material is flexible but strong enough to prevent tearing during installation or back filling. The membrane is non-toxic, resistant to soil acids and easy to install even in cold weather; the outside temperature was -4 degrees Celsius when the pictures were taken. Manufacturers of foundation wraps claim that it is flexible enough to cover future cracks and virtually eliminates basement leaks. The membrane is durable and is expected to last 50 or more years. Shifting and settlement cracks will not affect the membrane's life expectancy.

The membrane is only fastened to the foundation at grade level. A cap should be installed at grade level to prevent water from getting in behind the membrane. The dimpled foundation is strong, easy to install, requires no maintenance and is unaffected by freeze/thaw cycles.

|

Foundation wrap is installed from expected

grade to bottom of footings

|

|

|

|